Couple months back Indy’s Escort dropped a Valve Seat and made quite the ruckus. The valve seat is a steel ring that is pressed into the cylinder head. It handles the violence that happens when a very hot valve slams into the softer cylinder head (now-a-day they’re mostly aluminum). They’re also used in classic cars that were designed for lead added fuel (oil companies stopped making it for public vehicles in the early 90’s – It is still used in small aircraft). With out lead in the fuel, classic cars can, over time, pull the hot valve though the iron cylinder head (sucking a valve). Lead added to the fuel helped with detonation (also called “pinging” or “knocking”), and it also softened the repeated hard contact between the valve and the cylinder head.

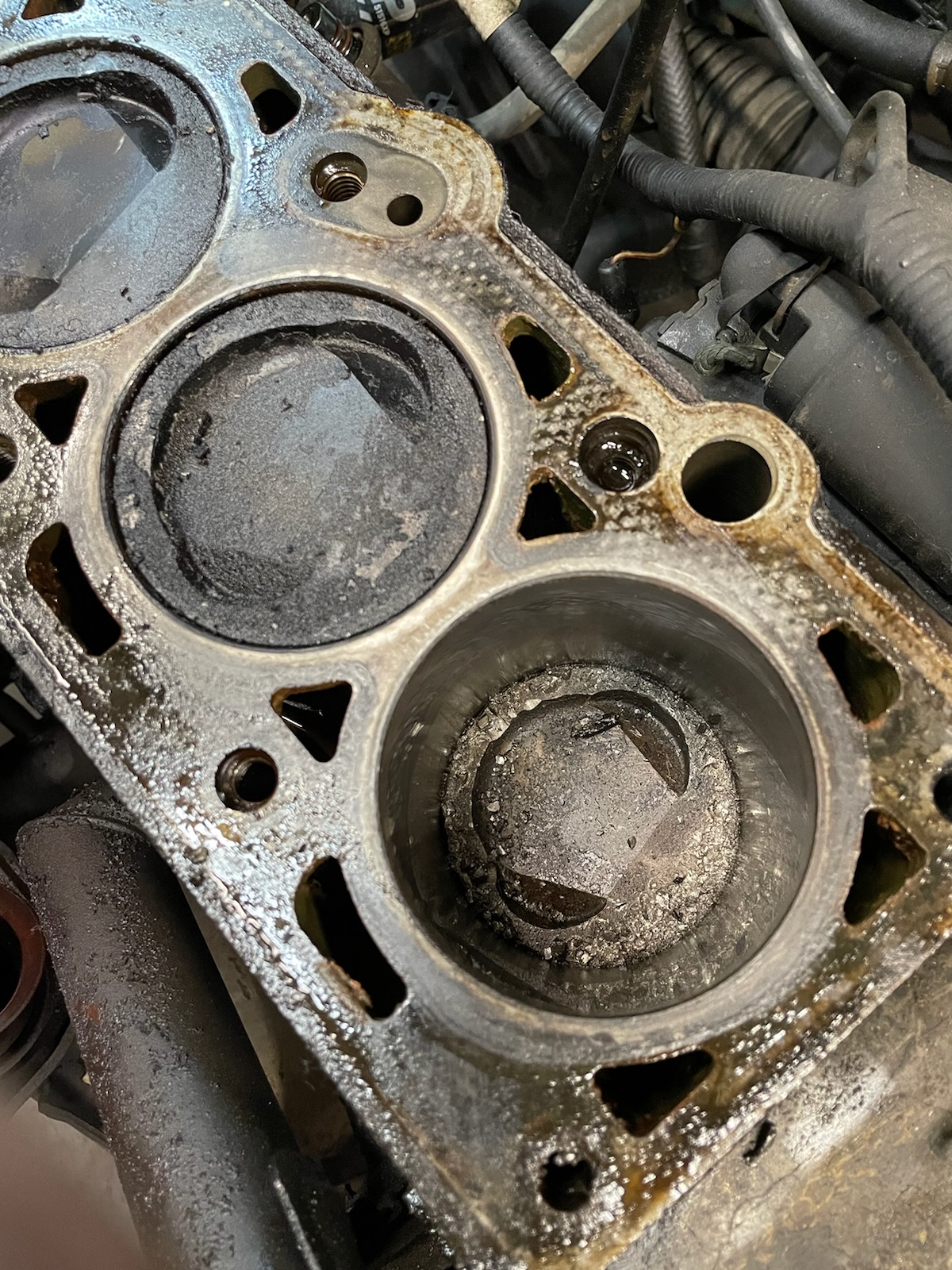

Anyhow, on the 1995 Ford Escort LX Wagon, it had a 1.9L in line 4. That motor was notorious for dropping valve seats. We found it had dropped a valve seat by using a borescope (tinny camera on the end of a flexible shaft). Inside the cylinder we saw shards of broken steel, and lots of dents in the top of the piston. Luckily for the pocketbook, the block was free from scaring, and the cylinder head was able to be repaired.

Indy and I got busy taking it apart to see what the hell happened:

Here are a couple images of the aftermath:

Initially we hit up “The AutoBone” (AutoZone) for a replacement. The new cylinder head was supposed to be here about 4 days later for under $500. After a few weeks, after calling several times, it was finally revealed that it would be close to 6 months for a replacement. It is still listed on the web site for home delivery in a few days (I think they should maybe change that).

I went shopping for a machine shop that wasn’t booked out until 2034 (the year I can retire) or cost as much as a mortgage payment. I called a few places, but when I got in contact with Tony at Chet’s Engines & Performance the price was good, and Tony sounded like a good guy.

The cylinder head also had some bad lifters (they push against the cam shaft and rocker arm to push the valve open). They’re filled with oil as the engine runs and become uncompressible. A few of the lifters had come loose internally and scrapped up the cylinder head. After a phone call, we (Tony and myself) decided to put new lifters in there and hope for the best.

Over last weekend (Memorial Day Weekend) Indy and I got to work cleaning it up and putting it together. I had already cleaned it up a little, but it needed to be spotless for re-assembly.

Cleaned up for pictures – not cleaned up enough for assembly:

After we got the new (rebuilt) cylinder head, we cleaned the block up well, wiped out the cylinders, cleaned everything with Brake Cleaner “I see Unicorns and Rainbows!” and got ready to start bolting all back together (more than that, but I doubt anyone needs to hear about replacing the timing belt, water pump, and repainting the exhaust manifold).

It doesn’t matter how much I clean the engine for reassembly, it never feels clean enough. Head gaskets are a notoriously weak spot for small motors, so I made sure to read and watch as many cylinder head related videos as I could find to make sure I had done enough. The new cylinder head had been steam cleaned, brushed, and soaked so it looked basically brand spankin’ new. We chased the threads for the head bolts with a tap set, sprayed them out, and with a little Loctite for security we were ready to start. I walked Indy through setting up the torque wrench, the pattern to snug them down, and let him have at it. These bolts are stretch bolts, so you do them in two steps. Torque them down (44 ft lbs if I remember), loosen them back up a couple turns, and torque them back down to the same torque (I think we went 45 ft lbs because tighter is gooder?).

When we started hooking all the things back up, we had to stop and tinker. Most things were old, so they kind of only went one direction (Isn’t that a band?). The electrical connectors are dummy proof so you cannot really connect them incorrectly.

Indy also wire brushed, cleaned, and painted the exhaust manifold. Normally there is an aluminum shield over the exhaust manifold, but it wasn’t pretty, so we left it on the floor next to other odds and ends.

After we had checked and rechecked all the bits and pieces it was time to turn the key. When we started it the first time, I was happily surprised it started after the fuel made it back to the fuel rail. The motor started and ran fine, but the valve train noise was lauder than I had expected. It didn’t sound “expensive” but it didn’t sound as quiet as I had expected it to be. When we started it the second time it was very quiet for a few minutes before slowly getting louder. On the test drive it wasn’t quiet, but also didn’t sound “bad”. Looking back, I wonder if some of the noise on the test drive was pinging from the roughed-up piston. I think that is probably my personal biggest “unknown” for the longevity of the little motor that could. If it lets go, I guess we can start the V8 swap 🙂 .

Indy also worked on the brakes since his car was down for a while. It ended up having the wrong rotors, so we had to pull the new ones back off and put the old ones back on (After I scuffed the shine off of them). On the test drive Indy didn’t really have any brakes (e-brake action worked fine), so a day later he and Jamie went out and bled the brakes. I hear they work well now 🙂 .

Another issue we’re having is that the capacitor (also called an ignition resistor) arcs wildly when first starting the motor so that is unhooked until we can find a replacement (I have an old school version coming tomorrow that we can splice in). I think the wire jacket cracked from being old and me moving it around, so it is allowing the gobs of volts to arch around wildly (Ignition for spark plugs is usually 20,000 volts + but very little amperage).

Next for his car is probably some exhaust work, hook up some of the gauges we installed when he bought the car, and replace the axels (one of the CV boots is in bad shape – but fine until winter).

We’ve also got to get it inspected and registered. Next year he can register it as an Antique and lower yet another bill. Has anyone seen the bill of sale or title? 🙂